The flowrate of solids can be measured either as they leave the hopper or as they are conveyed. In the former case, the hopper may be supported on load cells so that a

continuous record of the mass of the contents may be obtained as a function of time. Alternatively, the level of the solids in the hopper may be continuously monitored using

transducers covered by flexible diaphragms flush with the walls of the hopper. The diaphragm responds to the presence of the solids and thus indicates whether there are

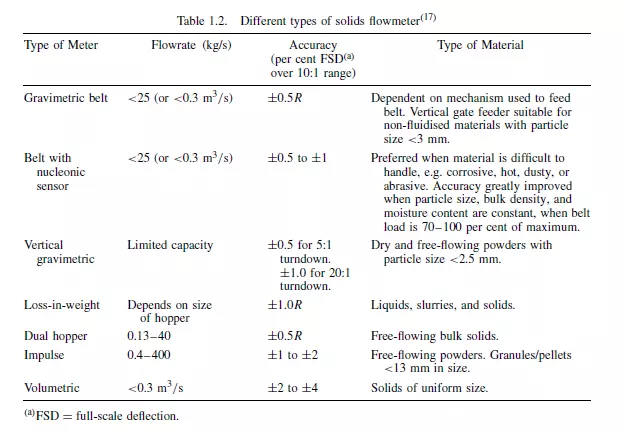

solids present at a particular level. The problems associated with the measurement and control of the flowrate of solids are much more complicated than those in the corresponding situation with liquids. The flow characteristics will depend, not only on particle size, size range and shape, but also on how densely the particles are packed. In addition, surface and electrical properties and moisturecontent all exert a strong influence on flow behaviour, and the combined effect of these factors is almost impossible to predict in advance. It is therefore desirable to carry out a preliminary qualitative assessment before making a selection of the, most appropriate technique for controlling and measuring flowrate for any particular application. A detailed description of the various methods of measuring solids flowrates has been given by LIPTAK(17) and Table 1.2, taken from this work, gives a summary of the principal types of solids flowmeters in common use.

Methods include:

a) Fitting an orifice plate at the discharge point from the hopper. The flow of solids through orifices is discussed briefly in Section 1.3.6.

b) Using a belt-type feeder in which the mass of material on the belt is continuously measured, by load cells for example or by a nuclear densitometer which measures

the degree of absorption of gamma rays transmitted vertically through the solids on the belt which is travelling at a controlled speed.

c) Applying an impulse method in which a solids stream impacts vertically on a sensing plate orientated at an angle to the vertical. The horizontal component of the resulting force is measured by as load cell attached to the plate.

The rate of feed of solids may be controlled using screw feeders, rotating tables or vibrating feeders, such as magnetically vibrated troughs. Volumetric rates may be

controlled by regulating the speeds of rotation of star feeders or rotary vaned valves.