The discharge rate of solid particles is usually controlled by the size of the orifice or the aperture at the base of the hopper, though sometimes screw feeders or rotating table feeders may be incorporated to encourage an even flowrate. The flow of solids through an orifice depends on the ability of the particles to dilate in the region of the aperture. Flow will occur if the shear force exerted by the superincumbent material exceeds the shear strength of the powder near the outlet. The rate of discharge of solids through the outlet orifice is substantially independent of the depth of solids in the hopper, provided this exceeds about four times the diameter of the hopper, and is proportional to the effective diameter of the orifice, raised to the power 2.5. The effective diameter is the actual orifice diameter less a correction which is equal to between 1 and 1.5 times the particle diameter. BROWN(16) has developed an equation for flow through an orifice, by assuming that the plug of solids issuing from the orifice has a minimum total potential plus kinetic energy.

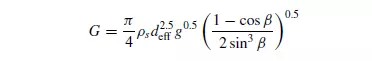

This gives:

where: G is the mass flowrate, ρs is the density of the solid particles, deff is the effective diameter of the orifice (orifice : particle diameter), g is the acceleration due to gravity, and β is the acute angle between the cone wall and the horizontal. It has been found that the attachment of a discharge pipe of the same diameter as the

orifice immediately beneath it increases the flowrate, particularly of fine solids. Thus, in one case, with a pipe with a length to diameter ratio of 50, the discharge rate of a fine sand could be increased by 50 per cent and that of a coarse sand by 15 per cent. Another method of increasing the discharge rate of fine particles is to fluidise the particles in the neighbourhood of the orifice by the injection of air. Fluidisation is discussed in Chapter 6.