Solids may be stored in heaps or in sacks although subsequent handling problems may be serious with large-scale operations. Frequently, solids are stored in hoppers which are usually circular or rectangular in cross-section, with conical or tapering sections at the bottom. The hopper is filled at the top and it should be noted that, if there is an appreciable size distribution of the particles, some segregation may occur during filling with the larger particles tending to roll to the outside of the piles in the hopper.

Discharge from the hopper takes place through an aperture at the bottom of the cone, and difficulties are commonly experienced in obtaining a regular, or sometimes any,

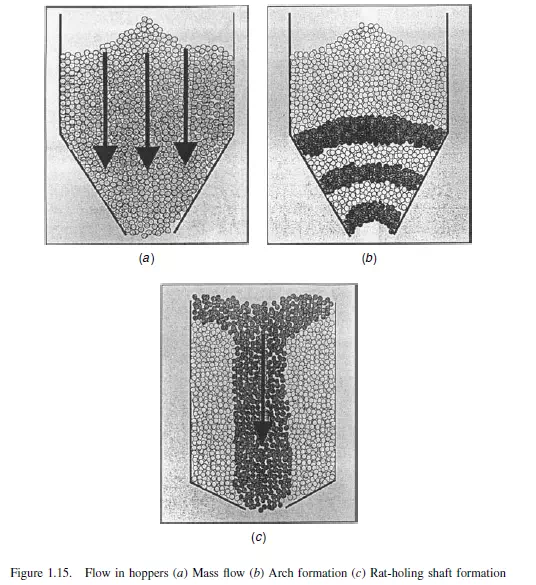

flow. Commonly experienced types of behaviour are shown in Figure 1.15 taken from the work of WEIGAND(15). Bridging of particles may take place and sometimes stable

arches (b) may form inside the hopper and, although these can usually be broken down by vibrators attached to the walls, problems of persistent blockage are not unknown. A further problem which is commonly encountered is that of “piping” or “rat-holing”(c), in which the central core of material is discharged leaving a stagnant surrounding mass of solids. As a result some solids may be retained for long periods in the hopper and

may deteriorate. Ideally, “mass flow” (a) is required in which the solids are in plug flow and move downwards en masse in the hopper. The residence time of all particles in the hopper will then be the same. In general, tall thin hoppers give better flow characteristics than short wide ones and the use of long small-angle conical sections at the base is advantageous. The nature of the surface of the hopper is important and smooth surfaces give improved discharge characteristics. Monel metal cladding of steel is frequently used for this purpose.