The solution of many of the pressing problems of society for the future (e.g., global warming, clean energy, manned missions to Mars) will depend significantly on chemical and bioengineers. In order to more fully explain

the role of chemical and bioengineers and to illustrate the role of chemical and bioengineers in solving society’s technical problems, we will now consider some of the issues associated with carbon dioxide capture and sequestration, which is directly related to global warming. Because fossil fuels are less expensive and readily available, we would like to reduce the impact of burning fossil fuels for energy, but without significantly increasing the costs.

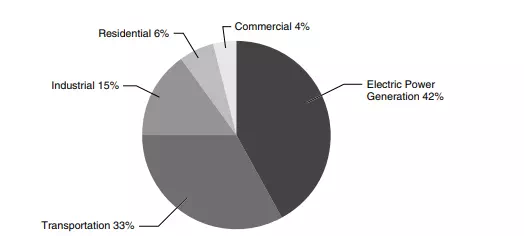

Therefore, it is imperative that we develop low-cost CO2 capture and sequestration technologies that will allow us to do that. An examination of Figure 1.1 shows the sources of CO2 emissions in the United States. What category would you attack first? Electric power generation is the number-one source. Transportation sources are widely distributed. No doubt power generation would be the most fruitful. Carbon capture and storage (CCS) is viewed as having promise for a few decades as an interim measure for reducing atmospheric carbon emissions relatively quickly and sharply while allowing conventional coal-fired power plants to last their full life cycles.

But the energy costs, the disposal challenges, and the fact that adding CCS to an existing plant actually boosts the overall consumption of fossil fuels (because of the increased consumption of energy to collect and sequester CO2, more power plants have to be built so that the final production of net energy is the same) all suggest that CCS is not an ultimate solution. One interim measure under serious consideration for CCS that might allow existing conventional coal-fired power plants to keep producing until they can be phased out at the end of their full lives involves various known technologies. An existing plant could be retrofitted with an amine scrubber

to capture 80% to 95% of CO2 from combustion gases; the CO2 would then be condensed into a liquid that would be transported and stored somewhere indefinitely where it could not leak into the atmosphere. If several hundreds or thousands of CCS systems were deployed globally this century, each capturing 1 to 5 metric tons of CO2 per year collectively, they could contribute between 15% and 55% of the worldwide cumulative mitigation effort. However, the engineering challenges are significant.

First, CCS is an energy-intensive process, so power plants require significantly more fuel to generate each kilowatt-hour of electricity produced for consumption. Depending on the type of plant, additional fuel consumption ranges from 11% to 40% more—meaning not only in dollars, but also in additional fossil fuel that would have to be removed from the ground to provide the power for the capture and sequestration, as well as additional CO2 needing sequestration by doing so. Current carbon-separation technology can increase the price tag of producing electricity by as much as 70%. Put another way, it costs about $40 to $55 per ton of carbon dioxide.

The annual U.S. output of carbon dioxide is nearly 2 billion tons, which indicates the economic scale of the problem. The U.S. Department of Energy is working on ways to reduce the expenses of separation and capture