The needs of the practitioner involved in industrial drying are completely different to those of the standards expert. He is not generally interested in predicting or measuring values of humidity and temperature accurate to several decimal places; in the challenging environment of a dryer exhaust he is pleased to have any instrument which keeps working and gives a reading accurate to the nearest degree or a few % RH. Humidity helps with shortcut calculations for dryer design and performance and in identifying trends as operating conditions vary.

Psychrometric charts and dryer sizing

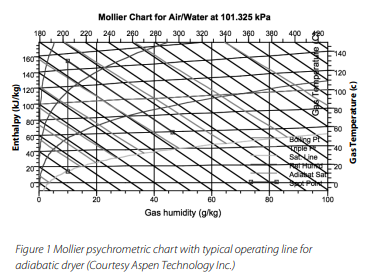

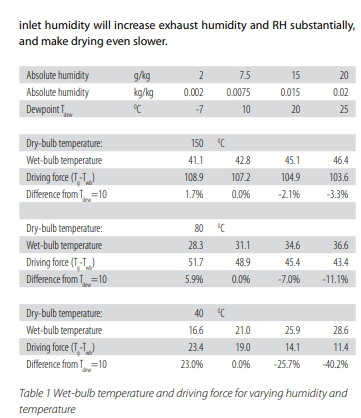

The familiar Grosvenor temperature-humidity psychrometric chart is not the only one used in drying. Enthalpy-humidity psychrometric charts are also extremely useful. The enthalpy plotted is the total of the sensible heat and latent heat of the gas-vapour mixture. There are two types; Mollier (non-orthogonal, used in UK and Europe) and Bowen (orthogonal, used in USA). The constant-enthalpy lines on the Mollier chart slope downwards with a gradient proportional to the latent heat. Though less intuitive initially, it is clearer to read in practice as the information tends to be cramped together on the Bowen chart. The charts provide a useful visual representation of gas-phase conditions during drying processes. Psychrometric charts are very useful for rapid sizing of convective (air heated) dryers, by finding what airflow will be needed. The sensible heat lost from the gas as it is cooled becomes latent heat of vapour which returns to the mixture, and the total gas-vapour mixture enthalpy remains roughly constant. Hence, the air conditions during drying roughly follow a constant-enthalpy line. This provides a simple visual way of determining dryer outlet conditions and performing a short-cut design calculation. Allowing a suitable safety margin above the dewpoint, say 200 C, the exhaust temperature and the corresponding humidity can be read off from the chart. A simple mass balance on the moisture in the gas gives the required airflow. For example, suppose we want to dry 1 tonne/hr of wet solid from 15% moisture to 3%. The required evaporation rate is 12% of 1 te/h, or 120 kg/h. If we use air at 1500 C with an inlet humidity of 10 g/kg, the chart (Figure 1) shows the wet-bulb temperature is about 420 C Assuming an outlet temperature of 600 C, we find that the dewpoint is 400 C and exhaust humidity 46 g/kg. The humidity change over the dryer is 36 g/kg (0.036 kg/kg) so to evaporate 120 kg/h we will need (120/0.036) or 3330 kg/h of air. A safety margin of about 10% can be added to allow for heat losses.