There are two distinct methods of feeding material to a crusher. The first, known as free crushing, involves feeding the material at a comparatively low rate so that the product can readily escape. Its residence time in the machine is therefore short and the production of appreciable quantities of undersize material is avoided. The second method is known as choke feeding. In this case, the machine is kept full of material and discharge of the product is impeded so that the material remains in the crusher for a longer period. This results in a higher degree of crushing, although the capacity of the machine is reduced and energy consumption is high because of the cushioning action produced by the accumulated product. This method is therefore used only when a comparatively small amount of materials is to be crushed and when it is desired to complete the whole of the size reduction in one operation. If the plant is operated, as in choke feeding, so that the material is passed only once

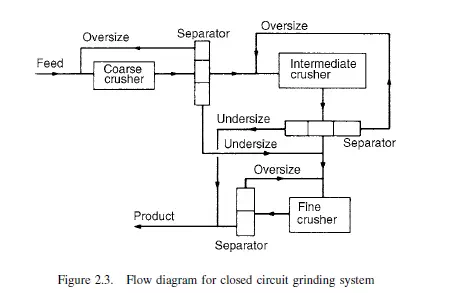

through the equipment, the process is known as open circuit grinding. If, on the other hand, the product contains material which is insufficiently crushed, it may be necessary to separate the product and return the oversize material for a second crushing. This system which is generally to be preferred, is known as closed circuit grinding. A flow-sheet for a typical closed circuit grinding process, in which a coarse crusher, an intermediate crusher and a fine grinder are used, is shown in Figure 2.3. In many plants, the product is continuously removed, either by allowing the material to fall on to a screen or by subjecting it to the action of a stream of fluid, such that the small particles are carried away and the oversize material falls back to be crushed again.

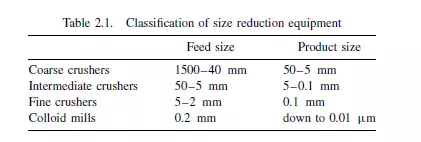

The desirability of using a number of size reduction units when the particle size is to be considerably reduced arises from the fact that it is not generally economical to effect

a large reduction ratio in a single machine. The equipment used is usually divided into classes as given in Table 2.1, according to the size of the feed and the product.

A greater size reduction ratio can be obtained in fine crushers than in coarse crushers.

The equipment may also be classified, to some extent, according to the nature of the force which is applied though, as a number of forces are generally involved, it is a less

convenient basis. Grinding may be carried out either wet or dry, although wet grinding is generally applicable only with low speed mills. The advantages of wet grinding are:

a) The power consumption is reduced by about 20–30 per cent.

b) The capacity of the plant is increased.

c) The removal of the product is facilitated and the amount of fines is reduced.

d) Dust formation is eliminated.

e) The solids are more easily handled.

Against this, the wear on the grinding medium is generally about 20 per cent greater, and it may be necessary to dry the product. The separators in Figure 2.3 may be either a cyclone type, as typified by the Bradley microsizer or a mechanical air separator. Cyclone separators, the theory of operation and application of which are fully discussed in Chapter 1, may be used. Alternatively, a whizzer type of air separator such as the NEI air separator shown in Figures 1.29 and 1.30 is often included as an integral part of the mill, as shown in the examples of the NEI pendulum mill in Figure 2.21. Oversize particles drop down the inner case and are returned directly to the mill, whilst the fine material is removed as a separate product stream.