Rupture disks are often used in combination with and installed just upstream and/or just downstream of a relief valve. You may want to choose the combination option if:

|

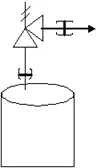

| Figure 3: Rupture Disk-Relief Valve Combination |

1. You need to ensure a positive seal of the system (the system contains a toxic substance and you are concerned that the relief valve may leak). Application: rupture disk installed upstream of the relief valve.

2. The system contains solids that may plug the relief valve over time. Remember, the relief valve is continuously exposed to the system. Application: rupture disk installed upstream of the relief valve.

3. TO SAVE MONEY! If the system is a corrosive environment, the rupture disk is specified with the more exotic and corrosion resistant material. It acts as the barrier between the corrosive system and the relief valve. Application: rupture disk installed either upstream and/or downstream of the relief valve.

Below is a capital cost comparison between combination Hastelloy C rupture disks with stainless steel relief valves and three stand-alone Hastelloy C relief valves. Again, this is based on a budget estimate in year 2001 dollars using Continental Disc Corp. rupture disks and holders and Farris Engineering relief valves.

| Basis: Continental Disc | Basis: Farris Engineering |

| 3″ Ultrx Hast C Holder = $3,300 | 3″ x 4″ Hast C 26KA10-120 = $13,400 |

| 3″ Ultrx Hast C Disc = $2,600 for 1st usable disk, then $870 each | 3″ x 4″ SS 26KA10-120 = $4,300 |

Combination of Hastelloy C Disk and SS Relief Valve

Single Installation Total = $10,200

Total for three installations = $27,140

Three stand-alone Hastelloy C relief valves = $40,200

Summary

A stand-alone rupture disk is used when:

1. You are looking for capital and maintenance savings

2. You can afford to loose the system contents

3. The system contents are relatively benign

4. You need a pressure relief device that is fast acting

5. A relief valve is not suitable due to the nature of the system contents

A rupture disk / relief valve combination is used when:

1. You need to ensure a positive seal of the system

2. The system contains solids that may plug the relief valve over time

3. TO SAVE MONEY! If the system is a corrosive environment, the rupture disk is specified with the more exotic and corrosion resistant material