Why Do We Use a Stand-Alone Rupture Disk?

A rupture disk is just another pressure relieving device. It is used for the same purpose as a relief valve, to protect a vessel or system from overpressure that can cause catastrophic failure and even a death.

When Do We Use a Stand-Alone Rupture Disk?

Some of the more common reasons are listed below. You may think of others.

|

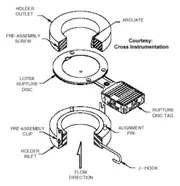

| Figure 1: Basic Components of a Rupture Disk |

1. Capital and Maintenance Savings: Rupture disks cost less than relief valves. They generally require little to no maintenance.

2. Contents will be lost, but who cares? A rupture disk is a nonreclosing device, which means once it opens, it doesn’t close. Whatever is in the system will get out and continue to do so until stopped by some form of intervention. If loss of contents is not an issue, then a rupture disk may be the relief device of choice.Â

3. Benign service: It is preferable that the relieving contents be non-toxic, non-hazardous, etc. However, this is not a requirement when deciding to use, or not use, a stand-alone rupture disk.

4. Rupture disks are extremely fast acting: Rupture disks should be considered first when there is a potential for runaway reactions. In this application, relief valves will not react fast enough to prevent a catastrophic failure. A relief valve may still be installed on the vessel to protect against other relieving scenarios. Some engineers prefer to use rupture disks for heat exchanger tube rupture scenarios rather than relief valves. They are concerned that relief valves won’t respond fast enough to pressure spikes that may be experienced if gas/vapor is the driving force or liquid flashing occurs.

|

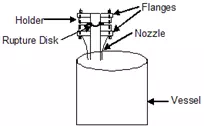

| Figure 2: Rupture Disk Mounted on a Vessel |

5. The system contents can plug the relief valve during relief: There are some liquids that may actually freeze when undergoing rapid depressurization. This may cause blockage within a relief valve that would render it useless. Also, if the vessel contains solids, there is a danger of the relief valve plugging during relief.

6. High viscosity liquids. If the system is filled with highly viscous liquids such as polymers, the rupture disk should seriously be considered as the preferable relieving device. Flow through a relief valve will be very difficult to calculate accurately. Also, very viscous fluid may not relieve fast enough through a relief valve.